Our manufacturing in detail.

Workshop acc. Nuclear Standards

Acc. nuclear customer requirements to meet nuclear standards have we built a workshop with a crane system where we manufacture, assemble and store exclusively components and manipulators made of austenitic and other non-ferrous metals.

There is also sufficient space for test setups.

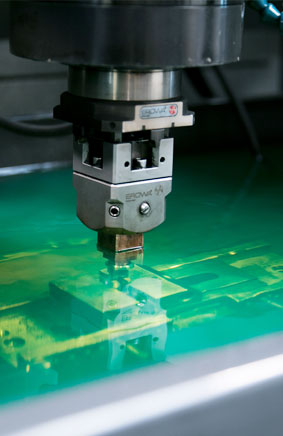

Electrical Discharge Machining (EDM)

Wire eroding of complex workpieces up to max. 320 x 115 x 180 mm. We also have machine-related software with an involute program for eroding gear teeth accurately.

Sink erosion of all conceivable forms and contours. Our highly-qualified staff use graphite and copper electrodes for this. Here we are able to machine workpieces with dimensions of up to 800 x 500 x 200 mm. Larger components can also be clamped by adapting an additional table. The feasibility of clamping the workpiece is evaluated on a case-by-case basis.

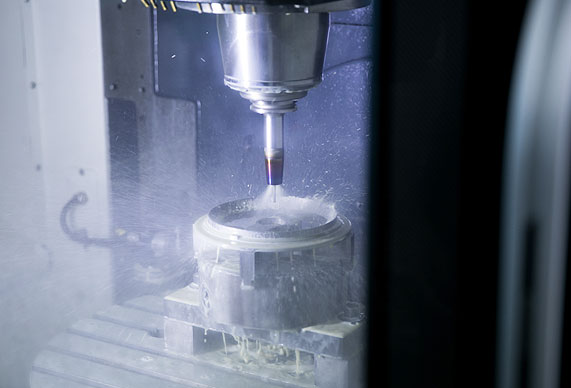

High-Speed Cutting (HSC)

In recent years, high-speed cutting has become a popular machining method. Compact, extremely accurate and versatile: as a true all-rounder, our high-speed machining centre will give you excellent performance, especially when manufacturing high-precision mini-electrodes.

We are able to machine workpieces with dimensions of up to 400 x 300 x 300 mm.

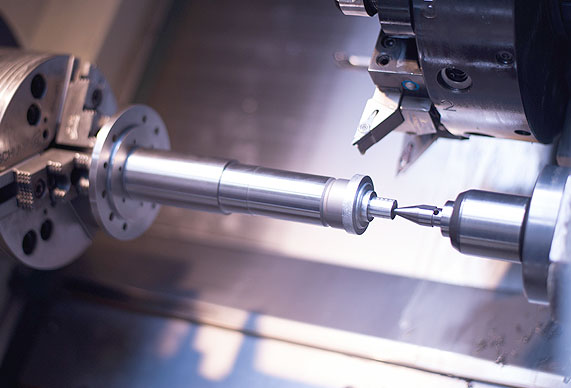

Turning

On our lathes we manufacture parts made from all machinable materials.

Whether an individual part or small-batch production, on our modern CNC machining centres we can manufacture any kind of turned component: according to a drawing, a sample or to your individually-specific requirements. We are able to machine workpieces with dimensions of up to Ø 400 x 800 mm length.