NDT custom reference standards

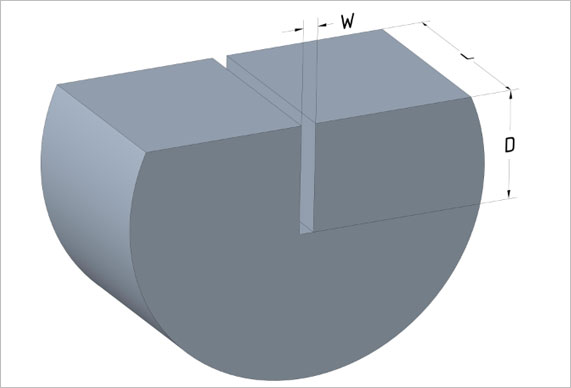

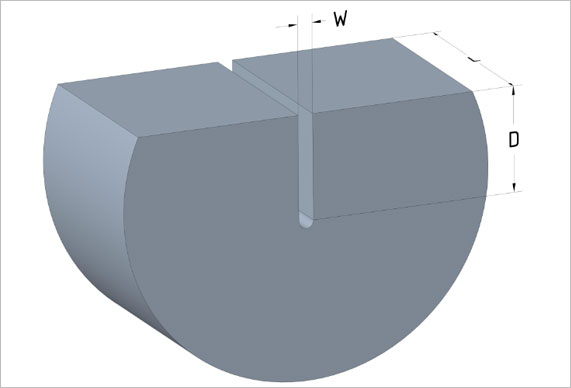

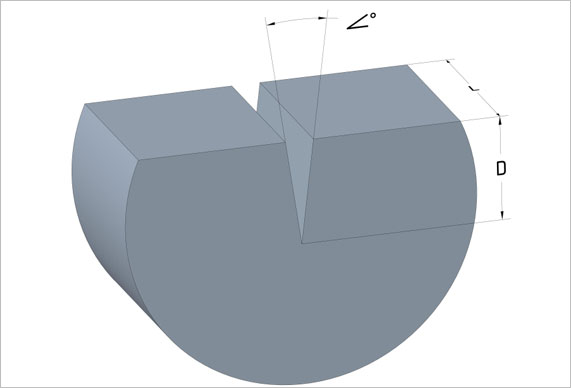

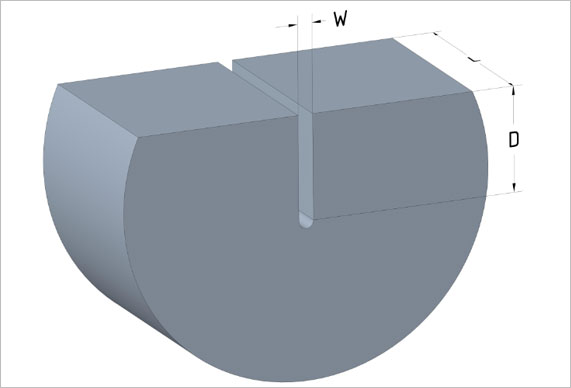

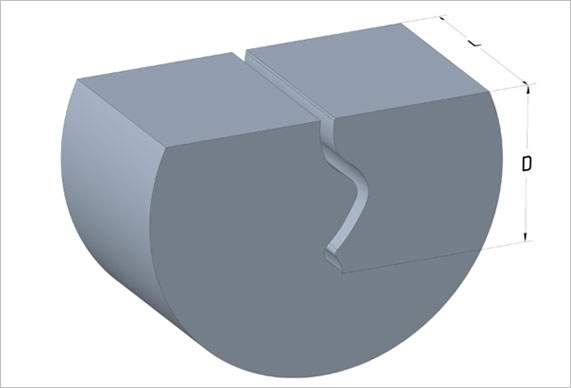

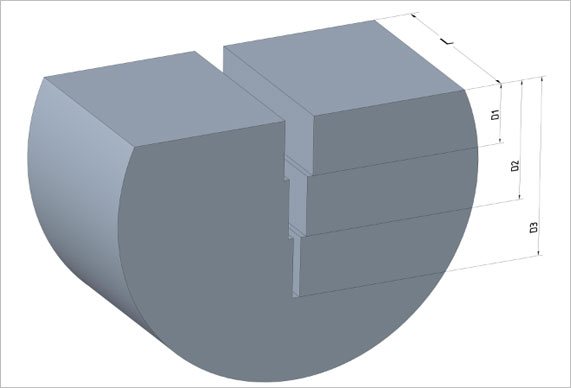

EDM notch shapes

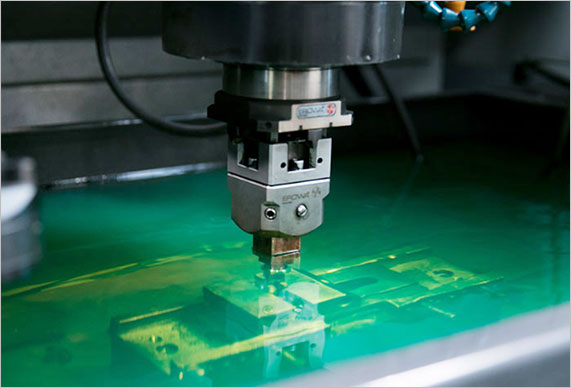

Knauer & Rösch is highly-specialized in producing artificial discontinuities known as electrical discharge machined (EDM) notches. EDM notches are typically produced from an otherwise acceptable production item supplied by the manufacturer of the part or the test lab performing the inspection. When selecting what type of EDM notch is right for your application, it is important to consider both the width and length cross-section of the notch. There are various geometries available that all have their purpose for testing applications.

wide min: 0.13 mm 30mm depth – wide 0.8 mm

Corner Radius 0.03 mm